Osprey® Ti-6Al-4V-ELI (Grade 23)

Request a quoteTitanium alloys

Osprey® Ti-6Al-4V-ELI (Grade 23)

Osprey® Ti-6Al-4V-ELI (Grade 23) is a titanium grade alloyed with aluminium and vanadium, especially developed for Additive Manufacturing (according to ASTM F3001-14), as well as for HIP.

- UNS

- R56407

- ASTM, AISI

- F3001-14

- EN Number

- 3.7165

- SAE

- AMS7015

Powder designed for

- Additive Manufacturing (AM)

- Hot Isostatic Pressing (HIP)

- Metal Injection Moulding (MIM)

This powder is manufactured by Electrode Inert Gas Atomization (EIGA), producing a powder with a spherical morphology which provides good flow characteristic and high packing density.

-

Product description

Osprey® Ti-6Al-4V-ELI* (Grade 23) is a titanium grade alloyed with aluminium and vanadium, especially developed for Additive Manufacturing (according to ASTM F3001-14), as well as for Hot Isostatic Pressing (HIP).

The grade is characterized by high strength, very good corrosion resistance and low density. It is similar to Osprey® Ti-6Al-4V (Grade 5) but has a lower content of oxygen, nitrogen and iron, resulting in, for example, higher ductility. Osprey® Ti-6Al-4V-ELI (Grade 23) is typically used for medical implants as well as for aerospace and chemical processing applications.

Osprey® titanium powder is manufactured to the highest international quality management standards, for example, AS9100D (aerospace).

*Extra low interstitials

Product description

Osprey® Ti-6Al-4V-ELI* (Grade 23) is a titanium grade alloyed with aluminium and vanadium, especially developed for Additive Manufacturing (according to ASTM F3001-14), as well as for Hot Isostatic Pressing (HIP).

The grade is characterized by high strength, very good corrosion resistance and low density. It is similar to Osprey® Ti-6Al-4V (Grade 5) but has a lower content of oxygen, nitrogen and iron, resulting in, for example, higher ductility. Osprey® Ti-6Al-4V-ELI (Grade 23) is typically used for medical implants as well as for aerospace and chemical processing applications.

Osprey® titanium powder is manufactured to the highest international quality management standards, for example, AS9100D (aerospace).

*Extra low interstitials

Osprey® Ti-6Al-4V-ELI* (Grade 23) is a titanium grade alloyed with aluminium and vanadium, especially developed for Additive Manufacturing (according to ASTM F3001-14), as well as for Hot Isostatic Pressing (HIP).

The grade is characterized by high strength, very good corrosion resistance and low density. It is similar to Osprey® Ti-6Al-4V (Grade 5) but has a lower content of oxygen, nitrogen and iron, resulting in, for example, higher ductility. Osprey® Ti-6Al-4V-ELI (Grade 23) is typically used for medical implants as well as for aerospace and chemical processing applications.

Osprey® titanium powder is manufactured to the highest international quality management standards, for example, AS9100D (aerospace).

*Extra low interstitials

Technical data

Page updated Sep 18, 2023 10:46 AM CET (supersedes all previous editions)

Downloads

-

Chemical composition (nominal), %

- Ti

- Bal.

- Al

- 5.50-6.50

- V

- 3.5-4.5

- Fe

- ≤0.25

- O

- ≤0.13

- C

- ≤0.08

- N

- ≤0.05

- H

- ≤0.012

- Y

- ≤0.005

- Other, each

- ≤0.10

- Other, all

- ≤0.40

-

Powder characteristics and morphology

SEM micrographs of -63 +20 µm powder with a spherical morphology (HS Circularity 0.95), smooth surface and low level of powder satellites (magnifications x100 and x250) and a section through the powder (magnification x1000), with no visible internal porosity.

SEM micrographs of -63 +20 µm powder with a spherical morphology (HS Circularity 0.95), smooth surface and low level of powder satellites (magnifications x100 and x250) and a section through the powder (magnification x1000), with no visible internal porosity. -

Particle size distribution

Powder for Additive Manufacturing

Osprey® metal powder for Additive Manufacturing is available in a wide range of particle size distributions that are tailored to the individual Additive Manufacturing systems. They can also be tailored to the particular requirements of the end application, both in terms of mechanical performance and surface finish.

Typical particle size distributions for Additive Manufacturing.

Typical particle size distributions for Additive Manufacturing.Typical particle size distributions for Additive Manufacturing Process technology Size (µm) Binder jetting ≤ 16, ≤ 22, ≤ 32, ≤ 38, ≤ 45 Laser - Powder Bed Fusion (L-PBF) 15 to 53 and 10 to 45 Electron beam - Powder Bed Fusion (E-PBF) 45 to 106 Direct Energy Deposition (DED) 53 to 150

Powder for Hot Isostatic Pressing (HIP)

Osprey® powder for Hot Isostatic Pressing (HIP) is available in a broad size range, typically <250 microns, resulting in a high packing density and tap density. Low oxygen levels, together with high packing density, also facilitate faster sintering.

Powder for Metal Injection Moulding (MIM)

Osprey® metal powder for Metal Injection Moulding (MIM) is available in a wide range of particle size distributions, from under 5 μm up to 38 μm. The table shows our standard particle size distributions for MIM powders.

Size (μm) D10 (μm) D50 (μm) D90 (μm) Typical particle size distributions for Metal Injection Moulding (MIM)* ≤ 38 5.5 13.0 31.0 ≤ 32 5.0 12.0 29.0 80% ≤ 22 4.5 11.5 27.0 90% ≤ 22 4.0 10.5 22.0 90% ≤ 16 3.5 8.0 16.0 * Particle size measurements performed using a Malvern laser particle size analyzer, typical D10, D50 and D90 provided.

Tailor-made particle size distributions are available on request. Contact us to discuss your specific requirements.

-

Microstructure

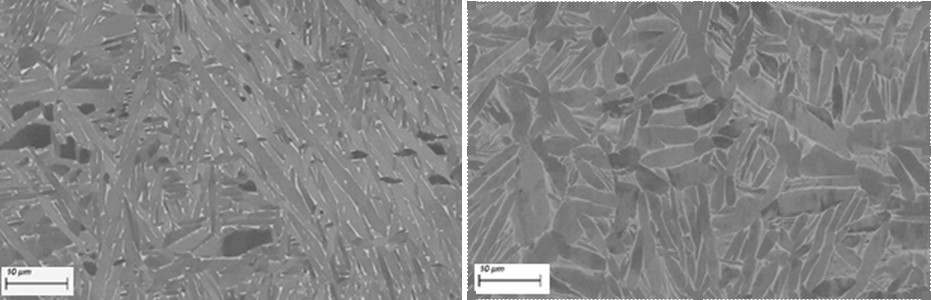

SEM micrographs of Osprey® TI-6AL-4V-ELI (Grade 23) Laser - Powder Bed Fusion (L-PBF) material in a heat-treated condition (solution annealed at 850 °C/1,562 °F for 2h in argon) on the left, featuring a fine lamellar and dense microstructure is identified which originates from the decomposition of martensitic α’ as expected; showing a phase transformation that gave rise to a coarser structure consisting of a α phase matrix (grey) and an interlamellar β phase (bright).

The difference in microstructure for vertical and horizontal builds is not significant. The mechanical properties of heat-treated L-PBF material are provided below. The microstructure, shown on the right, for L-PBF material after Hot Isostatic Pressing (HIP), which results in a coarsening of the grain size. The mechanical properties of HIP material are similar to that of the heat-treated material with an improvement in impact toughness, especially in the vertical direction.

SEM micrograph of Osprey® TI-6AL-4V-ELI (Grade 23) Laser - Powder Bed Fusion (L-PBF) material in a heat-treated condition, featuring ductile fracture surface.

SEM micrograph of Osprey® TI-6AL-4V-ELI (Grade 23) Laser - Powder Bed Fusion (L-PBF) material in a heat-treated condition, featuring ductile fracture surface. SEM micrograph of Osprey® TI-6AL-4V-ELI (Grade 23) Hot Isostatic Pressing (HIP) material, featuring ductile fracture surface.

SEM micrograph of Osprey® TI-6AL-4V-ELI (Grade 23) Hot Isostatic Pressing (HIP) material, featuring ductile fracture surface. -

Mechanical properties

Typical mechanical properties of material produced by Laser - Powder Bed Fusion (L-PBF) after solution annealing at 850°C/1,562°F for 2h, followed by air cooling and a combination of solution annealing with Hot Isostatic Pressing (HIP) at 920°C/1,688°F for 2h with a pressure of 100 MPa/14.5 ksi, followed by furnace cooling.

Tensile properties in heat-treated condition, metric units Condition Direction Yield strength (Rp0.2), MPa Tensile strength (Rm), MPa E-modulus, GPa Elongation (A), % Impact toughness, J As built Horizontal 957 +/–7 1,076 +/–6 119 +/–2 14.4 +/–0.6 23 +/–0.5 As built Vertical 997 +/–6 1,094 +/–4 122 +/–2 15.5 +/–0.5 22 +/–0.9 HIP Horizontal 906 +/–2 1,014 +/–1 125 +/–3 17.7 +/–0.8 23 +/–0.7 HIP Vertical 915 +/–8 1,015 +/–4 126 +/–3 17.2 +/–0.4 23 +/–0.8 Tensile properties in heat-treated condition, imperial units Condition Direction Yield strength (Rp0.2), ksi Tensile strength (Rm), ksi E-modulus, ksi Elongation (A), % Impact toughness, ft/lb As built Horizontal 139 +/–1 156 +/–1 17,260 +/–290 14.4 +/–0.6 17.0 +/–0.4 As built Vertical 145 +/–1 159 +/–1 17,695 +/–290 15.5 +/–0.5 16.2 +/–0.7 HIP Horizontal 131 +/–1 147 +/–1 18,130 +/–435 17.7 +/–0.8 17.0 +/–0.5 HIP Vertical 133 +/–1 147 +/–1 18,275 +/–435 17.2 +/–0.4 18.4 +/–0.6 Hardness

Typical Vickers Hardness (HV) levels (ASTM E92, ISO 6507-1, JIS Z2244, GB/T 4340.1) as well as HRC values of Osprey® TI-6AL-4V-ELI (Grade 23) material in the Laser - Powder Bed Fusion (L-PBF) heat-treated condition.

Hardness in heat-treated and HIP condition Condition Direction HV HRC Heat treated Horizontal 344 +/–4 34 Heat treated Vertical 346 +/–4 34 HIP Horizontal 329 +/–4 32 HIP Vertical 329 +/–4 32 Surface roughness

Typical surface roughness (Ra), of Osprey® TI-6AL-4V-ELI (Grade 23) in the Laser - Powder Bed Fusion (L-PBF) heat-treated condition.

Surface roughness for heat-treated condition Direction Roughness (RA), µm Horizontal 8.4 +/–0.9 Vertical 9.0 +/–0.2 High cycle fatigue at 350MPa, of Osprey® TI-6AL-4V-ELI (Grade 23) in the L-PBF heat-treated condition, at different build orientations and surface roughness conditions.

-

Testing

All Osprey® metal powders are supplied with a certificate of analysis containing information on the chemical composition and particle size distribution. Information on other powder characteristics is available upon request.

-

Packaging

A wide range of packaging options are available, from 1 kg (2.2 lb) to 200 kg (440 lb)*.

Contact our team who can support you with selecting the right packaging for your product and application.

*Some packaging options may not be available for all products due to international shipping regulations.

Disclaimer: Data and recommendations are for guidance only, and the suitability of a powder for a specific process or application can be confirmed only when we know the actual conditions. Continuous development may necessitate changes in technical data without notice. This datasheet is only valid for Osprey® powder.

Osprey® Online

Buy Osprey® Ti-6Al-4V-ELI (Grade 23) for additive manufacturing from our online store, available directly from stock.

Range of titanium alloys

| Osprey® | Standards* | Ti | Al | V | Fe | O | C | N | H | Y | Other, each | Other, all | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| CP-Ti (Grade 1) | UNS R56407 | Bal. | - | - | ≤0.2 | ≤0.18 | ≤0.08 | ≤0.03 | ≤0.015 | - | - | - |

CP-Ti (Grade 1)

|

| CP-Ti (Grade 2) | UNS R56407 | Bal. | - | - | ≤0.3 | ≤0.25 | ≤0.08 | ≤0.03 | ≤0.015 | - | - | - |

CP-Ti (Grade 2)

|

| Ti-6Al-4V-ELI (Grade 23) | UNS R56407 / ASTM, AISI F3001-14 | Bal. | 5.50-6.50 | 3.5-4.5 | ≤0.25 | ≤0.13 | ≤0.08 | ≤0.05 | ≤0.012 | ≤0.005 | ≤0.10 | ≤0.40 |

* Information about more standards is available in the datasheet for the respective alloy.

Get in touch with our experts in metal powder today